We will see the first smartphones equipped with Corning Gorilla Glass Victus 2 in the next months.

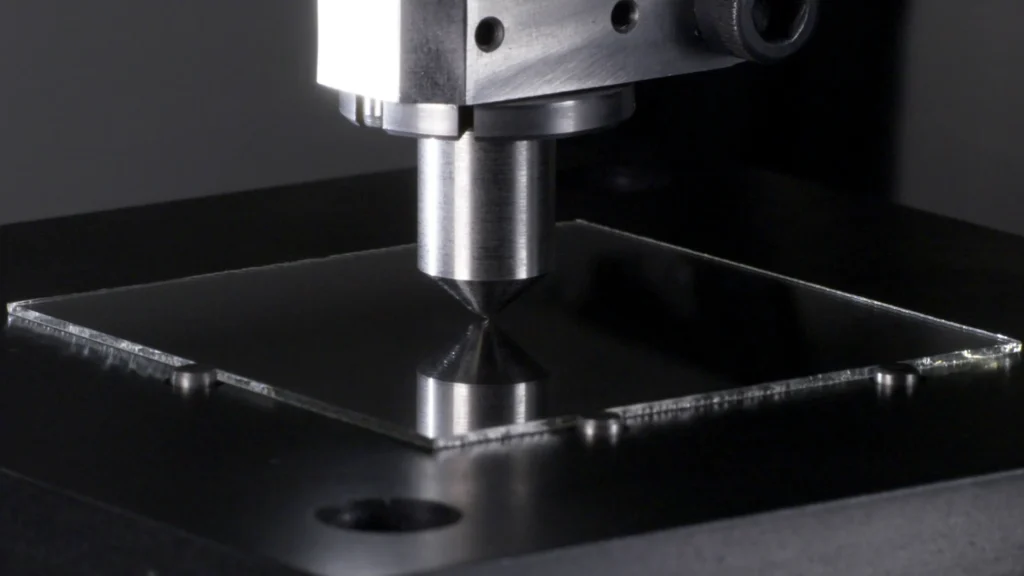

On Wednesday, Corning unveiled Glass Victus 2, an updated version of its popular glass that performs better when dropped on hard surfaces like concrete. We’re always looking for ways to improve the product, whether that’s in terms of drop or scratch resistance. According to Senior Vice President and General Manager of Mobile Consumer Electronics, John Bayne’s comments to The Indian Express suggest that „we have once again improved the drop performance of the glass“ with Victus 2.

Know what is Corning’s Gorilla Glass Victus

Bayne said Corning had to design a new test for the Victus 2, as the earlier version launched in July 2020 was already „so good“. Consequently, the puck weight increased from 165 grams to 190 grams, or 15%. We also went from testing on asphalt which you may find in a parking lot to concrete, which is a nastier material to test a glass surface,„he said, adding that Victus 2 survives multiple drops from about one meter on the concrete where competitive classes wouldn’t survive a single drop.

We should see the first smartphones equipped with Corning Gorilla Glass Victus 2 in the next months. To paraphrase, „often when we launch a premium flagship glass, it is adopted on premium phones. Then, our older glass production generations make their way to the budget and intermediate price points. What you’re seeing is the result of natural selection, he said. However, Bayne noted that there are exceptions to this trend, with certain manufacturers choosing to utilise superior glass even in the value sectors since it results in reduced return rates and less damage to the phone, therefore providing more value to users.

With Gorilla Glass protecting more than 8 billion devices from more than 45 major brands, Corning is now the world’s leading cover glass manufacturer. Glass and optics for semiconductor products are also produced by the company.

Bayne elaborated on the trend toward stronger and tougher glass, noting that these improvements have not come at the expense of glass’s ability to thin down without sacrificing safety. However, protective composite glass for foldable form factors is still a ways off. Though we aren’t quite there yet, we believe that a glass solution will eventually emerge on the market for flexible electronics. Significant difficulties exist in terms of development. We’ve come a long way. Bayne added, „We think we are getting close,“ though he reiterated that he would not commit to a certain timeframe. But I do think a glass surface will be what protects the interior of a bendable device in the long run. Why? Because that’s what the market demands. People prefer glass to plastic because it does not scratch as easily. And the time when we can finally sell this product is rapidly approaching.

Corning, which thanks to its production prowess has not suffered much throughout the pandemic, is also seeing other component constraints alleviating to some level today. Because of inflation and the economic downturn, we believe that supply is currently a lower problem than demand. As a result, we anticipate that this will be a short-lived trend, and that phone purchases will increase again in 2023 and 2024.

You may like reading the following news:

iPhone 15 to OnePlus 11 Pro: 5 most-anticipated flagship smartphones of 2023

Bimal Mardi is a Professional Content Writer. He works in First Santal Broadcast Network TV/ News channel in India. Bimal Mardi writes about Technology, Education and Tech Product Reviews